-

You are here:

- Home

- > News

- > Industry Information

What are the components of the compressed air piping system?

What are the components of the compressed air piping system?

The air in nature is compressed by an air compressor and is called compressed air. Compressed air is an important source of power.

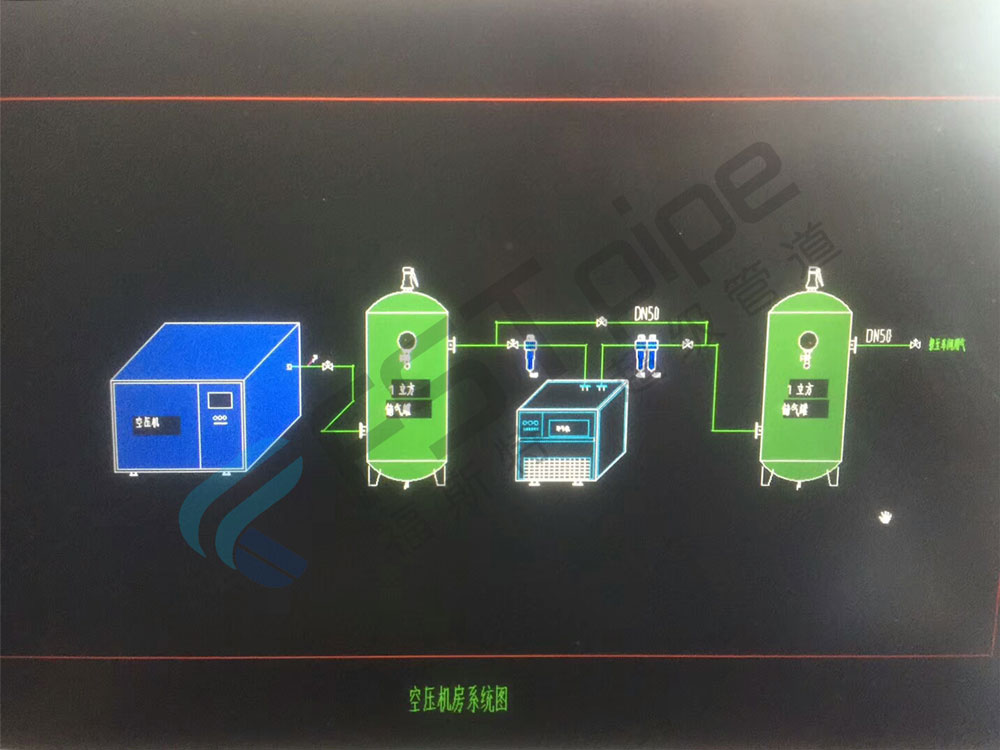

air compressor station production process

Compressed air production processes mainly include air filtration, air compression, compressed air cooling, oil and moisture removal, compressed air storage and transportation.

Air compressor

Among the general compressed air stations, the most widely used is a piston air compressor. In large compressed air stations, centrifugal or axial air compressors are often used.

Gas tank

Piston compressors are equipped with a gas tank to reduce the periodic pulsation of the compressor discharge, stabilize the pipe network pressure, and further separate the oil and moisture in the air.

Air dryer

The role of the air dryer is to further remove moisture from the compressed air to meet certain requirements for users who supply dry compressed air. Currently used compressed air drying methods include adsorption and freezing.

Oil water separator

The function of the oil-water separator is to separate the oil and moisture in the compressed air, so that the compressed air is initially purified. The oil-water separator is commonly used in the form of a toroidal rotary type, an impact folding type and a centrifugal rotation type.

Compressed air station piping system

The piping system of the compressed air station is: air line, cooling water line, oil water blowing line, load regulating line and dispersing line.

Laying of compressed air lines in the workshop

The compressed air pipeline in the workshop is divided into a main pipe, a trunk pipe and a branch pipe. The compressed air pipeline in the workshop can be laid by aerial installation, trench laying, underground laying, or overhead laying and underground laying combination.