-

You are here:

- Home

- > News

- > Company News

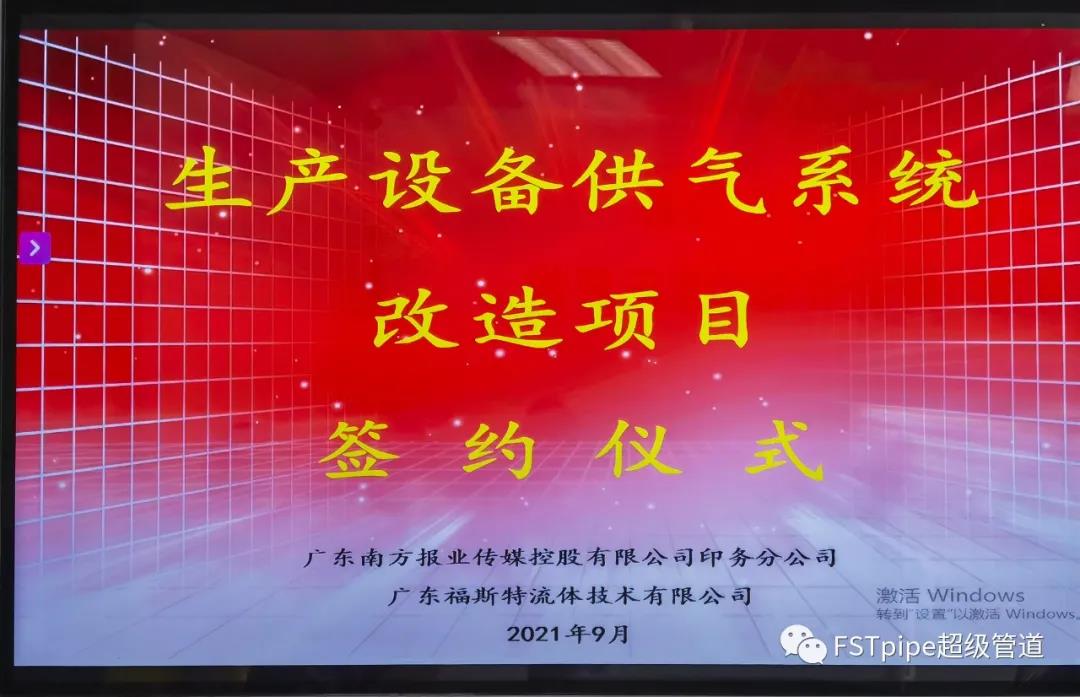

Signing ceremony of Guangdong Foster Fluid Technology Co., Ltd. and Guangdong Nanfang News Media Holdings Co., Ltd.

Go hand in hand to promote development together. On the afternoon of September 7, Guangdong Foster Fluid Technology Co., Ltd. and Guangdong Nanfang News Media Holdings Co., Ltd. carried out a signing ceremony for the renovation of the production equipment gas supply system, and the two parties reached a cooperation.

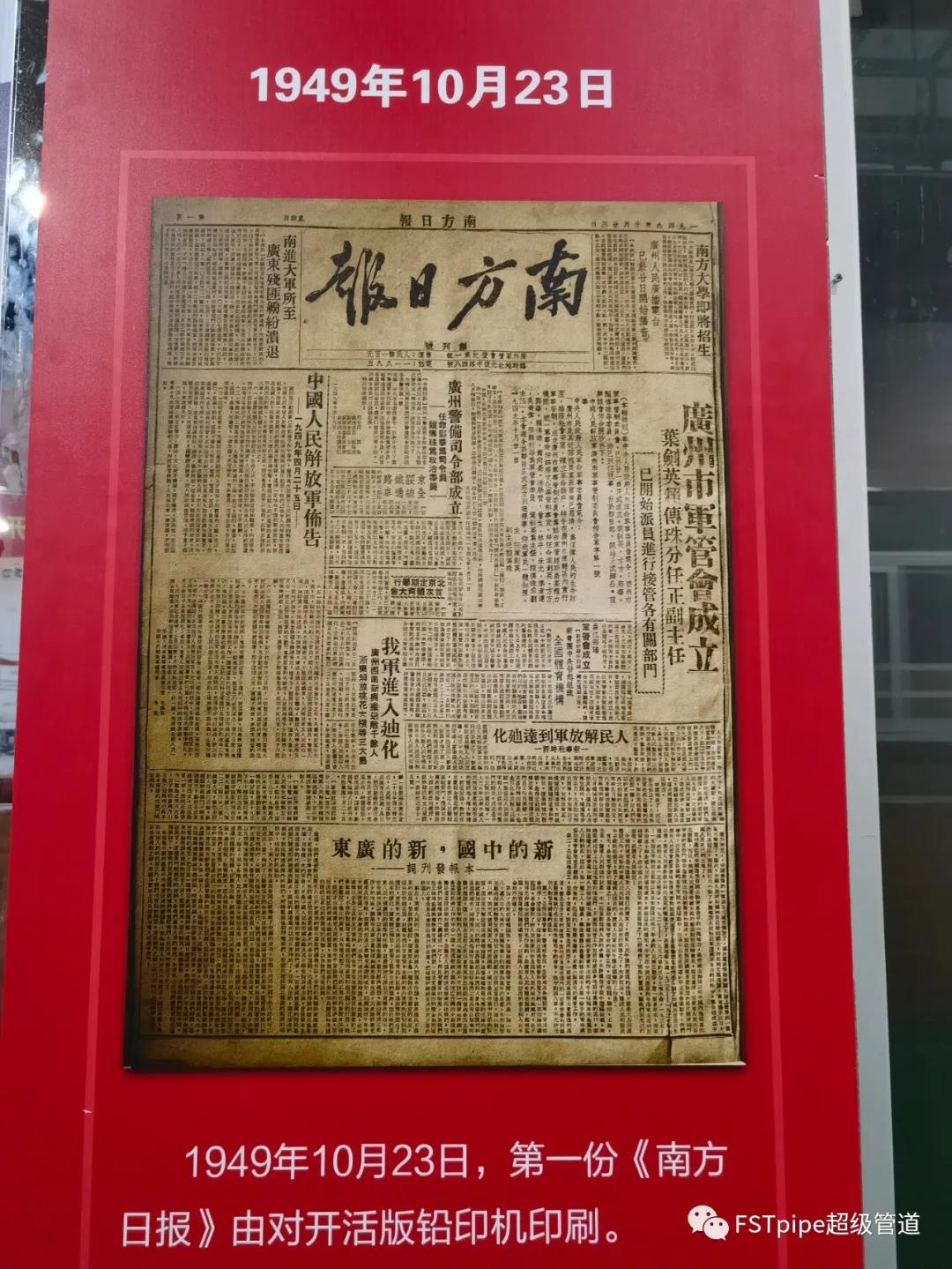

Before signing the contract, Chen Guoqiang, deputy general manager of Guangdong Nanfang News Media Holdings Co., Ltd., led FSTpipe's leaders to visit the production workshop and introduce the company's cultural history. Mr. Chen said: Nanfang Printing is the same age as Nanfang Daily and the same age as New China. On October 23, 1949, on the 23rd day after the founding of New China and the ninth day after the liberation of Guangzhou, on the same day that Nanfang Daily, an organ of the South China Branch of the Central Committee of the Communist Party of China, was published, Nanfang Printing was born.

From the three letterpress "master presses" at the beginning of the establishment of the factory, to today's 12 production lines, 76 towers of advanced printing equipment, the newspaper printing capacity per hour is 4.42 million pairs, ranking first in the country's newspaper industry. From the first printing of Nanfang Daily, today it is the first in the country in terms of newspaper types and print volume. From the dilapidated, narrow four-story building on Guangfu Middle Road, to today’s modern production plant of 70,000 square meters in the Southern News Media Industry Base Park. The decades that Southern Printing has gone through are only a brief moment in the long history, but they are extraordinary. After going through the twists and turns of the blue ray, bitterness and bitterness, we finally ushered in today's magnificent years. In accordance with the group's deep integration and comprehensive transformation strategy, Nanfang Printing is working towards the goal of building a printing center for the South China newspaper industry and promoting the transformation of the base from internal production operations to external service management parks.

At the signing ceremony, Mai Bingyuan, general manager of Guangdong Nanfang News Media Holdings Co., Ltd., said: Due to the political peculiarities and timeliness of the newspaper industry, Nanfang News has undergone a total of 6 factory relocations since its establishment and guaranteed no one-day suspension of production. With the aging of the pipeline system, the original system can no longer meet the existing production needs, and compressed air is an important source of power for the production process, so it was decided to update the pipeline of the entire production system and intelligently control it. After the project was established, I began to investigate many domestic and foreign pipeline brands. From the comparison, I learned about the excellent characteristics of FSTpipe products, professional pre-sales, in-sales, and after-sales services, reliable quality and stable performance. Therefore, Southern Guangdong News Media Holdings Co., Ltd. finally chose Guangdong Foster Fluid Technology Co., Ltd. as the supplier of the gas supply system renovation project. Subsequently, Wang Fuli, general manager of Guangdong Foster Fluid Technology Co., Ltd., introduced FSTpipe's development history and corporate culture, as well as the advantages of aluminum alloy pipe characteristics, and explained the importance of environmental protection and energy saving in today's society. The special super pipeline helps enterprises to save energy and reduce carbon, green development, and provide enterprises with a more environmentally friendly and energy-saving solution.

FSTpipe General Manager Wang Fuli said: After signing the contract, FSTpipe will promptly organize the construction plan and carry out various tasks to ensure the safe, efficient and smooth completion of the project without affecting the production.

FSTpipe provides professional pre-sale technical services and professional technical information consultation for every customer. Go deep into the construction site of the customer’s plant, survey the structure of the customer’s plant, draw drawings based on customer needs, and create a dual-optimized solution that is both rational and not lacking in order to achieve the best results in the operation of the compressed air pipeline system in the later stage, and to fully energy-saving and environmental protection . Our aim is to ensure that the customer's investment brings out the best benefits.